Table of Contents

- 1 Introduction to Low-Pressure Amalgam Lamps

- 2 What is Amalgam Lamp Technology?

- 3 LightSources’ Proprietary Pellet Amalgam Technology

- 4 Benefits of Pellet Amalgam Over Spot Amalgam:

- 5 Applications of Low-Pressure Amalgam UV Lamps

- 6 LightSources’ LongLife+™ Technology

- 7 Custom Solutions and Innovations by LightSources

- 8 Why Choose LightSources’ Amalgam UV Lamps?

LightSources offers innovative low-pressure amalgam lamps custom-engineered for industries seeking efficient and reliable germicidal solutions.

Introduction to Low-Pressure Amalgam Lamps

Ultraviolet (UV) germicidal technology harnesses the power of UV light to deactivate the DNA of bacteria, viruses, and other pathogens, preventing them from multiplying and causing disease. This technology is crucial in a variety of applications, ranging from water purification to air and surface disinfection. Within the spectrum of UV germicidal solutions, low pressure amalgam UV lamps represent a significant advancement, enhancing the efficiency and output of traditional UV disinfection methods.

Amalgam UV light technology plays a pivotal role in this advancement by increasing the power density and electrical efficiency of UV lamps. These amalgam UV bulbs utilize an amalgam, an alloy of mercury with other metals, to optimize UV output at a broader range of operating temperatures compared to standard low pressure UV lamps. This makes low pressure amalgam lamps particularly effective in environments where maintaining consistent UV output is challenging due to fluctuating temperatures.

What is Amalgam Lamp Technology?

Amalgam technology refers to the use of an amalgam—a solid solution or alloy of mercury with one or more metals—as the primary means of enhancing UV light output in low pressure UV lamps. This technology is critical in extending the operational stability and efficiency of UV lamps across a broader temperature spectrum. In the context of UV germicidal lamps, amalgam is used to maintain a more consistent vapor pressure of mercury within the lamp, which is crucial for sustaining optimal UV output.

Pellet and Spot Amalgam Technologies

In the realm of amalgam UV lamps, there are primarily two types of technology: pellet and spot amalgam. Pellet amalgam technology, a significant innovation developed and patented by LightSources in the United States and by LightTech in Europe, offers several advantages over the traditional spot amalgam approach.

Patented Pellet Amalgam Lamps: Learn More

Low pressure amalgam lamps are designed to produce higher UVC output at full power and under varying power conditions, such as dimming scenarios. This capability allows for more effective germicidal action across a range of environmental conditions and power settings.

Difference between Pellet and Spot Amalgam

Difference between Pellet and Spot Amalgam

The primary difference between pellet and spot amalgam technology lies in their configuration and performance under different operational stresses. Pellet amalgam, consisting of small, compact pellets, provides a larger surface area for the mercury amalgam, enhancing the lamp’s efficiency and power stability. In contrast, spot amalgam typically involves a smaller amount of amalgam placed at specific points within the lamp, which can limit performance flexibility and overall UV output efficiency.

By utilizing pellet amalgam technology, LightSources’ lamps achieve greater UV intensity and maintain higher energy efficiency, making them ideal for critical applications in water and air purification systems where reliability and high performance are essential.

LightSources’ Proprietary Pellet Amalgam Technology

LightSources and its European partner, LightTech, have developed and patented an advanced form of UV lamp technology known as pellet amalgam. This innovation represents a significant leap forward in UV germicidal efficacy and operational versatility. Pellet amalgam technology utilizes small, compact pellets of amalgam rather than the traditional spot amalgam, which places the amalgam at specific points within the lamp. This method optimizes the distribution and efficiency of the mercury vapor within the lamp, crucial for generating consistent ultraviolet light.

LightSources and its European partner, LightTech, have developed and patented an advanced form of UV lamp technology known as pellet amalgam. This innovation represents a significant leap forward in UV germicidal efficacy and operational versatility. Pellet amalgam technology utilizes small, compact pellets of amalgam rather than the traditional spot amalgam, which places the amalgam at specific points within the lamp. This method optimizes the distribution and efficiency of the mercury vapor within the lamp, crucial for generating consistent ultraviolet light.

Benefits of Pellet Amalgam Over Spot Amalgam:

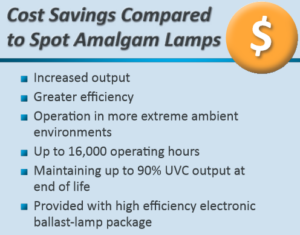

- Higher UVC Output: Pellet amalgam lamps are capable of producing higher UVC output both at full power and under varied power conditions. This makes them more effective in germicidal applications, especially under dimming conditions where spot amalgam lamps might falter.

- Versatile Mounting and Environmental Adaptability: Unlike traditional UV lamps, pellet amalgam lamps maintain high efficiency regardless of their mounting orientation—horizontal, vertical, or diagonal. They are also designed to perform optimally in a wide range of ambient environments, making them ideal for use in diverse operational settings where temperature and mounting flexibility are factors.

Detailed Features and Specifications of Spot & Pellet Amalgam Lamps

LightSources’ spot and pellet low-pressure amalgam lamps are designed to deliver exceptional performance and reliability, meeting the rigorous demands of modern germicidal applications:

- Outside Diameters: Available from 15mm to 38mm, these lamps accommodate a variety of fixture sizes and applications.

- Power Range: Ranging from 42W to 1,000W, these lamps cater to diverse intensity requirements for effective germicidal action.

- Stable UVC Output: These lamps provide consistent UVC performance across a broad air and water temperature range from 4°C to 40°C, which is crucial for maintaining efficacy under varying environmental conditions.

- Lamp Length: Capable of extending up to 2.5 meters, ensuring comprehensive coverage suitable for large-scale disinfection applications.

- High Wattage Efficiency: The higher wattage capabilities mean fewer lamps are required for the same output, leading to reduced capital and ongoing maintenance costs.

- Operating Hours: Engineered for longevity, these lamps offer an operating life of up to 16,000 hours, minimizing the need for frequent replacements.

- End-of-Life Efficiency: Maintains up to 85% of UVC output efficiency at the end of life, ensuring minimal performance degradation over time.

Additional Features Exclusive to Pellet Amalgam Lamps

- Enhanced UVC Output at Dimming Ranges: Pellet amalgam lamps are specially designed to provide superior UVC intensity per unit length, up to 1,700mW/cm, even at 80% to 50% dimming ranges, which is a capability not typically found in traditional UV lamps.

- Universal Mounting: These lamps support universal mounting options—horizontal, vertical, and diagonal—facilitating flexible installation and stable output performance in applications with very high glass wall temperatures.

- Stable output performance in very high glass wall temperature applications where the lamp is mounted vertically or diagonally

*Note: May require additional filament heating

*Higher-power Amalgam Lamps are available upon request

These features collectively underscore the adaptability and efficiency of LightSources’ amalgam lamps in a wide array of germicidal applications, ensuring both spot and pellet types meet industry-specific needs while providing cost-effective and robust disinfection solutions.

Universal Mounting Capability

Pellet amalgam lamps offer the flexibility of universal mounting, whether horizontal, vertical, or diagonal, without compromising on output performance. This feature is particularly beneficial in applications where space configuration and lamp orientation are critical.

These detailed specifications underscore the advanced capabilities of LightSources’ pellet amalgam lamps, making them a top choice for industries seeking efficient, reliable, and adaptable UV germicidal solutions.

Applications of Low-Pressure Amalgam UV Lamps

Low-pressure amalgam UV lamps from LightSources are instrumental in a range of applications that demand high efficiency and reliability. These lamps are particularly valuable in sectors where stringent disinfection standards are required:

- Healthcare: In healthcare settings, these lamps are used to disinfect surgical equipment, air, and surfaces, significantly reducing the risk of hospital-acquired infections.

- Municipal Water Treatment: They play a crucial role in water purification systems, ensuring safe drinking water free from bacteria, viruses, and protozoans. Their high UVC output makes them effective at breaking down harmful microorganisms and chemical contaminants.

- Industrial Processes: In industries such as pharmaceuticals, food and beverage, and electronics, low-pressure amalgam lamps are used to maintain disinfected conditions or to treat wastewater.

Benefits to System Designers: The high power density and efficiency of LightSources’ low-pressure amalgam UV lamps allow system designers to use fewer lamps while maintaining the same level of disinfection. This not only simplifies the design and reduces the physical footprint of treatment systems but also lowers energy consumption and operational costs, enhancing overall system sustainability.

LightSources’ LongLife+™ Technology

LightSources has developed a proprietary technology known as LongLife+™ that significantly enhances the life and performance of low-pressure amalgam lamps. This advanced technology involves a special proprietary coating process that combats the common problem of accelerated depreciation, which is often associated with higher-intensity lamps.

Benefits of LongLife+™:

- Extended Lamp Life: With LongLife+™, lamps have an operating life of up to 16,000 hours, which minimizes the frequency of replacements and reduces maintenance costs.

- High UVC Output Efficiency: The lamps maintain up to 85% of their UVC output efficiency at the end of their life. This consistent performance ensures effective germicidal action throughout the lifespan of the lamp, providing dependable protection against pathogens.

Custom Solutions and Innovations by LightSources

LightSources is not only a leader in UV lamp technology but also a pioneer in developing custom solutions tailored to specific industry needs and high-temperature applications.

- High-Temperature Applications: LightSources designs UV lamps that can operate efficiently in environments with high ambient temperatures, which is critical for certain industrial processes where standard lamps would fail.

- Custom Design Capabilities: Understanding that each industry has unique requirements, LightSources offers custom-designed lamps that meet specific wavelength, intensity, and size specifications.

These applications and innovations highlight LightSources’ commitment to providing products with custom solutions that drive industry standards and address client-specific challenges effectively.

Why Choose LightSources’ Amalgam UV Lamps?

Choosing LightSources for your UV germicidal lamp needs offers significant advantages over other suppliers. The proprietary pellet amalgam technology and LongLife+™ process ensure that each lamp not only meets but exceeds industry standards for efficiency, lifespan, and performance. LightSources is committed to innovation, continuously advancing the technology behind UV germicidal lamps to offer products that lead the market in terms of reliability and environmental safety.

The advantages of opting for LightSources’ amalgam UV lamps include:

- Superior Efficiency: Enhanced UV output ensures effective germicidal action with fewer lamps and lower energy consumption.

- Cost-Effectiveness: Longer lamp life and reduced maintenance requirements translate to lower overall costs for users.

- Versatility: Customizable options and robust design make these lamps suitable for a wide range of applications, from industrial to healthcare settings.

- Environmental Compliance: LightSources lamps are designed to meet current environmental regulations, aiding facilities in maintaining compliance with safety and environmental standards.

Low pressure amalgam lamps from LightSources represent a significant advancement in UV germicidal technology. With proprietary innovations such as pellet amalgam technology and LongLife+™, LightSources offers lamps that provide superior performance, extended lifespan, and high efficiency. Amalgam UV bulbs are pivotal in various critical applications, effectively addressing the unique challenges of each sector. As industries continue to demand more sustainable and effective solutions, LightSources remains at the forefront, delivering cutting-edge products that enhance safety and operational efficiency.

Explore the potential of advanced UV germicidal solutions with LightSources. Whether you are upgrading your existing systems or designing new installations, our team is ready to provide expert guidance and high-quality, customizable UV lamp options.

LightSources offers a comprehensive range of UV germicidal lamps, engineered with proprietary technology for enhanced efficiency and longevity. Our lamps are designed to meet diverse industry needs, ensuring optimal performance in any application with custom engineering and prototype development available. Contact us to explore how our advanced UV germicidal solutions can benefit your operations with low pressure amalgam lamps.

| UVC Spot Amalgam Germicidal Lamps |

Tube Diameter | BF – BF Length | Arc Length | Power¹ | Current¹,² | Voltage¹ | UV Output¹ @ 254 nm |

Rated¹ Life | |

|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | W | A | V | µW/cm² | W | hrs. | |

| Horizontal | |||||||||

| GPHA357T5L | 15 | 357 | 278 | 42 | 1.2 | 36 | 110 | 11 | 16,000 |

| GPHA843T5L | 15 | 843 | 764 | 110 | 1.2 | 88 | 320 | 35 | 16,000 |

| GPHA1000T5L | 15 | 1000 | 921 | 127 | 1.2 | 107 | 370 | 42 | 16,000 |

| GPHA1554T5L | 15 | 1554 | 1475 | 190 | 1.2 | 164 | 500 | 68 | 16,000 |

| GPHA357T6L | 19 | 357 | 278 | 57 | 1.8 | 32 | 130 | 13 | 16,000 |

| GPHA843T6L | 19 | 843 | 764 | 127 | 1.8 | 71 | 400 | 43 | 16,000 |

| GPHA1000T6L | 19 | 1000 | 921 | 150 | 1.8 | 84 | 460 | 52 | 16,000 |

| GPHA1554T6L | 19 | 1554 | 1475 | 240 | 1.8 | 134 | 630 | 87 | 16,000 |

| GPHHA357T6L | 19 | 357 | 278 | 65 | 2.1 | 31 | 140 | 14 | 16,000 |

| GPHHA843T6L | 19 | 843 | 764 | 172 | 2.1 | 82 | 490 | 54 | 16,000 |

| GPHHA1000T6L | 19 | 1000 | 921 | 207 | 2.1 | 99 | 570 | 65 | 16,000 |

| GPHHA1554T6L | 19 | 1554 | 1475 | 320 | 2.1 | 154 | 750 | 105 | 16,000 |

| UVC Pellet Amalgam Germicidal Lamps |

Tube Diameter | BF – BF Length | Arc Length | Power¹ |

Current¹,² |

Voltage¹ | UV Output¹ @ 254 nm |

Rated¹ Life | |

|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | W | A | V | µW/cm² | W | hrs. | |

| Universal Application | |||||||||

| GPHVA357T5L | 15 | 357 | 278 | 42 | 1.2 | 36 | 110 | 11 | 16,000 |

| GPHVA843T5L | 15 | 843 | 764 | 105 | 1.2 | 88 | 320 | 35 | 16,000 |

| GPHVA1000T5L | 15 | 1000 | 921 | 127 | 1.2 | 107 | 370 | 42 | 16,000 |

| GPHVA1554T5L | 15 | 1554 | 1475 | 190 | 1.2 | 164 | 500 | 68 | 16,000 |

| GPHVA357T6L | 19 | 357 | 278 | 57 | 1.8 | 32 | 130 | 13 | 16,000 |

| GPHVA843T6L | 19 | 843 | 764 | 127 | 1.8 | 71 | 400 | 43 | 16,000 |

| GPHVA1000T6L | 19 | 1000 | 921 | 150 | 1.8 | 84 | 460 | 52 | 16,000 |

| GPHVA1554T6L | 19 | 1554 | 1475 | 240 | 1.8 | 134 | 630 | 87 | 16,000 |

| GPHHVA1554T6L | 19 | 1554 | 1475 | 320 | 2.1 | 154 | 750 | 105 | 16,000 |

| GPHHA1554T10L | 32 | 1554 | 1434 | 471 | 5 | 95 | 1160 | 157 | 16,000 |

Note 1: Lamp data is based on measurements performed under laboratory conditions in air at room ambient temperature. Measurements were performed on a high-frequency, current limited electronic ballast and represent average values at 1 meter.

Note 2: LSI Amalgam lamps are designed for operation on a PREHEAT BALLAST only, unless otherwise noted.

This post is also available in:

Chinese (Simplified)

Chinese (Simplified)

This post is also available in:

Chinese (Simplified)

Chinese (Simplified)